Safety First

Every Task, The Safe Way, Every Time

R&R Pipeline embraces a “Safety First” approach with every task completed during the workday. Regardless of the task, R&R Pipeline’s team members have been trained to complete critical field tasks associated with installing new infrastructure.

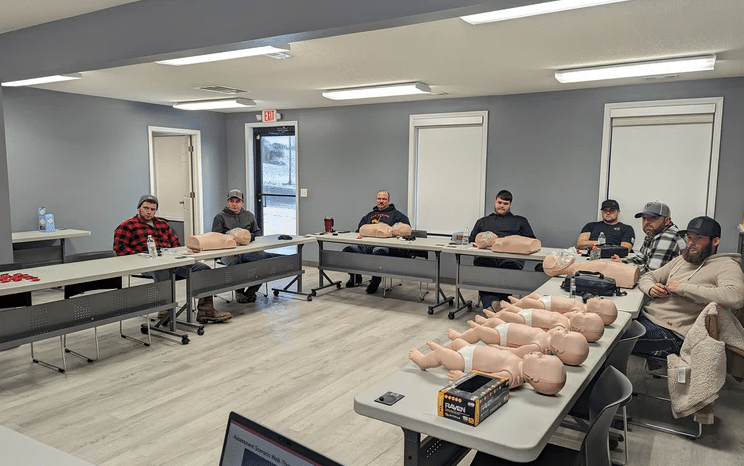

Our approach to training and certifying employees is based on providing classroom and field simulation experiences to ensure a safety-centric approach.

R&R Pipeline’s “top-down” approach to establishing the appropriate safety culture is focused on five key elements: Training, Safe-Driving, Tailgate Safety Meetings, Safety Equipment & Gear and Reporting.

OUR SAFETY RECORDS AND QUALITY STANDARDS ARE SECOND TO NONE IN THE INDUSTRY.

AT R&R PIPELINE, WE’RE COMMITTED TO PROVIDING A SAFE ENVIRONMENT FOR OUR WORKFORCE, AND THE COMMUNITIES THAT WE WORK IN.

Training

Each employee is trained to a higher standard to ensure that they are adequately prepared to complete the critical field tasks associated with a project. Additionally, employees obtain the necessary Operator Qualifications (OQ) to be compliant with ALL Federal, State, and Local requirements.

We have developed a 0-90 training program for all new hires, to ensure they hit the ground running safely. New Team members are provided with a guideline of tasks they will be tested on within the first 90 days.

This breaks up the training into more manageable sessions and informs the Team Members what they need to learn first and prepare for next.

Safe-Driving

Employees recognize that traveling to and from a worksite is as important as installing infrastructure. Adhering to speed limits, maintaining distance from other vehicles regardless of if they are moving or not, obeying traffic laws, and refraining from cell phone use while traveling are the cornerstones of our Safe Driving Standards.

Tailgate Safety Meetings

Prior to starting work at a jobsite each day, a Tailgate Safety Meeting is conducted with the participation of the assigned Project Manager, Foreman, Traffic Control Specialist, and Field Workers to openly discuss potential safety elements that could arise during the day. Understanding the potential daily risks assists our employees to maintain focus and ability to react in a worst-case scenario.

Safety Equipment & Gear

Each R&R Pipeline employee is equipped with appropriate fire-retardant clothing, hardhats, safety glasses, safety gloves, fire extinguishers, ear protection, and safety monitors/devices necessary to complete the infrastructure project at hand. Through the training process, tailgate safety meetings, and spot safety inspections, R&R Pipeline takes adherence to safety policy to a new level.

Reporting

R&R Pipeline reviews safety performance daily but tracks overall performance monthly. A “safety scorecard” or monthly metrics surrounding Preventable Vehicle Accidents (PVA), Days Away Reduced Time (DART), Experience Modifier Rate* (EMR), OSHA Violations, Near Misses, and we track and trend internal and client audits. Through this collective approach, R&R Pipeline continues to maintain a “best in class” safety record.